Water Heaters, Water Heater Repair, Water Heater Installation & Maintenance

Get the Service You Want and Need!

Quick Category Links for Water Heaters

When you need water heater repairs, water heater installations, or water heater maintenace, you can count on Able Plumbing.

This page is designed to give you a list of water heater repair and installation topics to browse and learn. If, after reading all about your water heater options, you are still stuck, have questions or just plain don't want to deal with it yourself, please reach out and call us. At Able Plumbing, we are trained professionals with over 35 years of local plumbing experience in Norther California.

When it comes to choosing and maintaining water heaters, you have many choices available.

Natural Gas Water Heaters

These energy efficient models provide hot water faster than most electric water heaters. This gives cost-efficient operations while producing fewer greenhouse gasses than other fossil fuels.

Electric Water Heaters

Though not as cost effective as using gas, electric water heaters can offer some installation benefits especially when access to gas lines is not economically feasible to the installation. Sometimes, these types of water heaters find great usefulness in commercial installations where smaller tanks capacities can be used.

Propane Water Heaters

Propane offers an alternative gas water heater for areas lacking natural gas lines, primarily in rural areas. These types of water heaters also offer cost-efficient operation options.

Heat Pump Water Heaters

Two to three times more energy-efficient than conventional electric resistance water heaters, this can lead to considerable energy and cost savings over time. Heat pump water heaters, also known as hybrid water heaters, operate on the principle of heat transfer rather than direct heating.

Tankless Water Heaters

Tankless water heaters offer the promise of endless hot water running through your home or business. Though installation of these water heaters can be expensive, not having to wait for hot water has been said to be well worth it. These types of water heaters can be gas or electric.

Under Sink Water Heaters

These types of water heaters offer convenience in tight spaces like bathrooms and kitchens. They come in tankless models as well as mini-tank water heater models. Find the capacity and flow rate that works for your needs.

Benefits of Recirculation Lines

- Faster Hot Water Access: Recirculation lines significantly reduce the time it takes for hot water to travel from the heater to the tap, providing almost instant hot water.

- Water Conservation: By minimizing the need to let water run while waiting for it to heat up, recirculation lines can save many gallons of water annually, benefiting both the environment and your utility bills.

- Energy Efficiency: Modern recirculation systems are designed with energy efficiency in mind. Many are equipped with timers and thermostats to operate only during peak usage times, minimizing unnecessary heating and pumping.

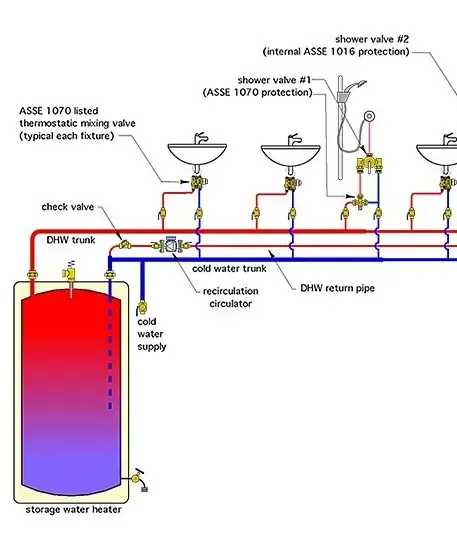

How Recirculation Lines Work

A recirculation system continuously pumps water from the water heater through the hot water pipes with a pump mechanism and back to the heater via a dedicated return line or through the cold water line with a specific valve. This loop keeps hot water moving and readily available at all points of use. Some systems activate on demand, using a switch or motion sensor, while others operate on a timer to ensure hot water availability during known peak times.

- Integrated System Using the Cold Water Line: This setup uses a pump and a special valve at the furthest fixture to allow the unused hot water to return to the heater through the cold water line, eliminating the need for a dedicated return pipe. It's easier to install in existing structures but may slightly warm the cold water line.

How Hydronic Radiant Heat Flooring Works

Hydronic systems circulate warm water through a network of tubing laid beneath the floor surface. The heat from the water radiates upward, warming the floor and the room above. The water is heated by a water heater and a return manifold system and can be controlled by zoning valves or thermostats to manage the temperature in different areas of the home. This method of heating provides an even, gentle warmth, eliminating the hot and cold spots commonly associated with traditional heating systems.

How Instant Hot Water Heaters Work

Most types have a small, insulated tank which contains the heated water. When the handle is pressed at the fixture, cool water will flow into the tank and displace the near-boiling water within the tank, which then flows out of the spout. On releasing the handle the valve closes and hot water stops flowing.

Benefits of Instant Hot Water Heaters

- Energy Efficiency: By heating water only when it's needed, instant hot water heaters can be more energy-efficient than traditional tank models, leading to lower utility bills.

- Water Savings: With a unit such as this, it will effectively eliminate the need to let the water run at the sink while waiting for it to get hot, creating water conservation of many gallons over a year.

- Cost Effective: Instant hot water heaters typically are more cost effective than a recirculation line especially if your hot water needs are smaller and/or mostly needed at one particular sink.

The Importance of Earthquake Straps

During an earthquake, the ground movement can cause unsecured water heaters to fall over. This can sever gas lines, leading to gas leaks, or damage water connections, causing flooding. Additionally, a toppled water heater poses a significant fire risk if it is a gas water heater (natural gas or liquid propane) and the gas line is ruptured. Earthquake straps help to mitigate these risks by securely anchoring the water heater to wall studs, ensuring it remains upright and intact during seismic events.

How Earthquake Straps Work

Earthquake straps are made of heavy-duty metal bands that wrap around the water heater, anchoring it to the wall or floor. For optimal safety, straps should be installed at both the top and bottom thirds of the water heater. This dual-point anchoring provides stability, preventing both horizontal and vertical movement during an earthquake. The straps are tightened to ensure a snug fit around the water heater, without compressing or damaging the unit.

Installation Considerations

- Compliance with Local Codes: Check your local building codes for specific requirements regarding earthquake strap installation, including the type of straps and anchoring methods approved for use in your area. Most areas of California require them.

- Water Heater Size and Type: Ensure that the earthquake straps you choose are suitable for the size and type of your water heater. Gas and electric water heaters may have different anchoring requirements due to their construction and utility connections.

- Location and Anchoring: Straps should be securely fastened to wall studs or masonry, not just to drywall or plaster. This may require locating studs behind the wall and drilling pilot holes for secure attachment.

- Professional Installation: While some homeowners may feel comfortable installing earthquake straps themselves, professional installation can ensure that the straps are correctly and securely fitted, providing maximum protection.

Whole Home Plumbing Inspections

Understanding the Inspection Process

A whole home plumbing inspection involves a detailed assessment of every component of your plumbing system. Our experienced plumbing technicians use advanced tools and techniques to check for leaks, corrosion, water pressure issues, and the general wear and tear on pipes and fixtures. They will typically review the functionality of your water heater, test the shut-off valves to ensure there are no leaks, check pipe (water and sewer) for signs of leaking or wear, check for proper pressure to the home, test all faucets and fixtures for proper flow, and ensure that your sump pump (if applicable) is working properly. This process not only helps in identifying current problems but also in predicting potential future issues that could save owners significant amounts of money in the long run.

Identifying Common Issues

During the inspection, common issues that may be uncovered include slow drains, which could suggest blockages or improper venting; low water pressure, which may indicate pipe corrosion or sediment build-up; and signs of water damage, which could point to leaks that have gone unnoticed. Our technicians also look for compliance with local building codes, which can affect insurance rates as well as the safety and value of the property. By addressing these issues early, homeowners can avoid the disruptions and extensive costs associated with major plumbing failures.

Temperature and Pressure: Understanding the Risks

- High Temperature: Setting the water heater temperature too high can lead to scalding injuries and increase energy consumption. The recommended setting for most households is around 120°F (49°C), which balances safety with the need to kill bacteria and minimize energy use.

- Excessive Pressure: Water pressure that is too high can stress the water heater and plumbing fixtures, leading to leaks or tank failure. Pressure issues often arise from thermal expansion as heated water increases in volume.

Temperature Solutions

- Thermostats: Water heaters are equipped with thermostats that allow homeowners to control the water temperature. Regularly checking and adjusting the thermostat can prevent overheating and reduce energy waste.

- Anti-Scald Devices: These devices, such as tempering valves and thermostatic mixing valves, mix cold water with hot at the outlet to ensure water is delivered at a safe temperature, especially important in homes with vulnerable residents, like children or the elderly.

Pressure Solutions

- Temperature and Pressure (T&P) Relief Valves: A critical safety feature on water heaters, the T&P valve, sometimes known as a TPR valve, automatically opens to release water if the temperature or pressure inside the tank becomes too high, preventing potential explosions.

- Expansion Tanks: Installed on the cold water supply line to the water heater, an expansion tank absorbs excess pressure caused by thermal expansion, protecting the system from pressure surges.

- Pressure Regulators: These devices are installed on the main water supply line to limit the water pressure entering the home and, consequently, the water heater, preventing stress on the system.

How Expansion Tanks Work

An expansion tank is divided into two sections by a rubber diaphragm also known as a bladder. One side is connected to the plumbing system and filled with water, while the other side contains pressurized air. As water volume expands upon heating known as thermal expansion, the excess water flows into the expansion tank, compressing the air on the other side of the diaphragm. This action absorbs the increased pressure, preventing it from stressing the water heater and plumbing fixtures.

The Importance of Expansion Tanks

- Protection Against Overpressure: By accommodating the expanded volume of water, expansion tanks prevent overpressure in the system, protecting against leaks in water heaters, ruptured pipes, and damaged valves.

- Compliance with Building Codes: Many regions require the installation of expansion tanks in new construction or when replacing a water heater, especially in closed-loop systems where backflow into the municipal water supply is prevented by a check valve or pressure reducing valve, usually near the meter.

- Enhanced System Longevity: By mitigating pressure fluctuations, expansion tanks contribute to the extended lifespan of water heaters and reduce the likelihood of premature system failure.

Installation Considerations

- Sizing: Proper sizing of the expansion tank is critical and depends on the size of the water heater and the typical thermal expansion expected in the system. An undersized tank won't effectively mitigate pressure, while an oversized tank can be unnecessarily expensive and take up more space.

- Location: Expansion tanks are typically installed on the cold water supply line near the water heater. This placement allows the tank to manage increased pressure before it affects the water heater and plumbing system.

- Orientation: While many expansion tanks are installed vertically, some models are designed for horizontal installation. The orientation does not typically affect performance but should align with the manufacturer's recommendations.

- Pressure Settings: The air pressure inside the expansion tank should be set equal to the water pressure of the home's plumbing system for optimal performance. This can usually be checked by using a water pressure gauge. This may require adjustment from the factory settings.

Importance of Drain Pans

- Leak Protection: Over time, water heaters can develop leaks due to corrosion, sediment buildup, or pressure issues. A drain pan collects this water, helping to prevent it from spreading and causing damage.

- Compliance with Building Codes: In many jurisdictions, installing a drain pan under water heaters, especially those located in attics or in closets inside the living spaces, is required by building codes.

- Peace of Mind: Knowing that pans will help to contain leaks provides owners with peace of mind, especially when the water heater is located in areas not regularly checked for leaks.

Types of Drain Pans

Drain pans come in a couple different materials and various sizes to suit different types and sizes of water heaters.

- Metal Pans: Typically made of aluminum, metal pans are durable and resistant to high temperatures. However, they can be susceptible to rust over time, especially if water remains standing in the pan.

- Plastic Pans: Made from high-impact plastic, these pans are rust-proof and often lighter and easier to install than metal pans. It’s important to choose a plastic pan that can withstand the temperature of discharged water.

Importance of Water Heater Stands

- Safety: The primary function of a water heater stand is to enhance safety by elevating the ignition source of gas water heaters, reducing the risk of flammable vapors being ignited.

- Flood Protection: In areas prone to flooding, raising the water heater can prevent water damage to the unit, prolonging its lifespan and ensuring continued operation.

- Compliance with Building Codes: Many local building codes require gas water heaters in garages and similar locations to be elevated, typically at least 18 inches off the ground, to meet safety regulations.

Specifications and Types

Water heater stands come in a couple of materials and various sizes, tailored to different types of water heaters:

- Metal Stands: Constructed from durable steel or aluminum, metal stands are designed to support the weight of a full water heater. They are available in fixed heights or adjustable models to accommodate different clearance requirements.

- Pre-Cast Concrete Blocks: Another option for elevating water heaters, especially in outdoor or unconditioned spaces, is using pre-cast concrete blocks. While less common, they offer stability and durability.

Annual Inspection For Water Heaters

- Visual Inspection: Annually inspect your water heater for signs of wear or damage, such as rust, corrosion, or water leakage around the base of the tank or in piping connections for traditional water heaters. For tankless models, check for any error codes or warning lights that may indicate a problem.

- Check the Temperature & Pressure Relief Valve (T&P): This safety device prevents excessive pressure buildup in the tank, which could lead to a dangerous explosion. Lift the valve's lever to release a little water into the drainpipe. If water doesn’t flow or continues to flow after testing, the valve may need to be replaced.

Drain and Flush the Tank

Sediment and/or calcium buildup can reduce your water heater's efficiency and clog water lines. For tank-style water heaters:

- Turn off the power: For electric heaters, switch off the power at the circuit breaker. For gas models, turn the thermostat to the "pilot" setting.

- Connect a garden hose to the drain valve: Direct the hose to a suitable drain or outdoors.

- Drain the tank: Open the drain valve and allow the water to flow out until it's clear of sediment. This may take several minutes to an hour. If the water remains murky, briefly turn on the cold water supply to help flush the tank.

Inspect Anode Rod

The anode rod protects your tank from corrosion by sacrificing itself to corrosion instead of the tank. Checking and replacing the anode rod every 3 to 5 years can significantly extend the life of your water heater.

- Locate and remove the anode rod: This will require an applicable wrench. Consult your water heater’s manual for the exact location and instructions or have one of our experts take care of it for you.

- Inspect the rod: If more than 6 inches of the core wire is visible, or the rod is heavily coated in calcium, it's time for a replacement.

Troubleshooting Water Heaters

1. No Hot Water

- Electric Water Heaters: Check if the circuit breaker has tripped. If so, reset it. If it trips again, there may be an electrical issue requiring a professional. For water heaters with two heating elements, one of the elements or thermostats may have failed and need replacement.

- Gas Water Heaters: Ensure the pilot light is on. If it's out, follow the manufacturer's instructions to relight it (typically located just above or on the control valve). If it won’t stay lit, the thermocouple might need replacing or the gas valve could be faulty.

2. Insufficient Hot Water or Running Out Quickly

- Sediment Buildup: Draining and flushing the tank can remove sediment affecting the heater's efficiency.

- Faulty Heating Element or Burner: For electric heaters, one of the heating elements may have failed. In gas models, the burner may be dirty or obstructed.

- Incorrectly Sized Water Heater: If your household's hot water demand has increased, you may need a larger water heater.

3. Water is Too Hot

- Thermostat Setting: Check the thermostat on the water heater; it should be set between 120°F and 130°F (check owner's manual if you see letters for the settings on the dial). Adjust accordingly if set too high.

4. Noisy Water Heater

- Sediment Buildup: Rumbling or popping noises are often due to sediment collecting at the bottom of the tank and overheating. Draining and flushing the tank can help.

- Water Hammer: If the noise occurs when turning hot water on or off, installing water hammer arrestors can solve the issue or ensuring pipes are properly strapped, especially if you've recently experienced an increase in your water pressure.